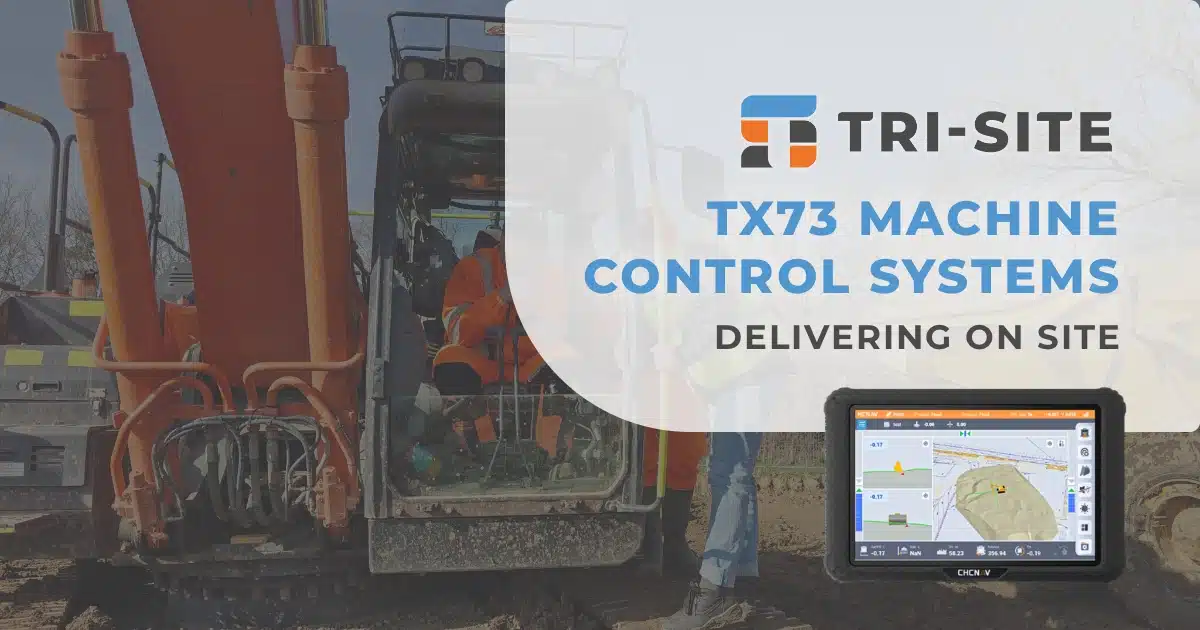

As demand grows for smarter, more efficient construction workflows, machine control systems are becoming essential on modern job sites. From improved design accuracy to reduced operator input and less rework, the right technology can have a real impact on productivity.

One system making a strong impression in the field is the CHCNAV TX73. Designed to work seamlessly across common formats and correction methods, it simplifies everything from design uploads to daily operation.

Seamless Integration

Potter Plant Hire has recently added a set of TX73 systems to its fleet, benefiting from quick integration with their Trimble-based setups. Design files are uploaded via the cloud in seconds, and the system handles standard file formats like DWG, DXF, LandXML and common coordinate systems without conversion headaches. This alone has saved site teams hours of prep and avoided typical format-based issues.

Operators have reported significant time savings and fewer errors thanks to features like automatic switching between left and right curve lines during road boxing. It’s these small, clever features that make the system stand out for those using it daily.

Support and training were also a major draw. For every five units purchased, CHCNAV supplies a desktop emulator for office-based driver training. That means new operators can be onboarded without taking machines out of service. And if issues do come up on site, remote login allows for quick troubleshooting without the need for callouts.

Built for Reliability and Support

The TX73 comes with a three-year hardware warranty and lifetime software updates, ensuring long-term value and peace of mind. It offers compatibility with VRS and RTCM radio corrections and supports a range of coordinate systems, making it flexible for varied site requirements. Pre-install kits are also available to speed up machine setup.

Why choose the TX73? It delivers true-to-design accuracy with no need for extra software conversions. The cloud-based design upload means teams stay updated in real time. The user interface is familiar and intuitive, helping operators get up to speed quickly. And compatibility with major machine manufacturers and tilt-rotor buckets means it integrates smoothly into existing systems.

A Smart Choice for Any Site

Whether you’re upgrading your current machine control setup or introducing it for the first time, the TX73 offers a straightforward, future-ready solution. Built for compatibility, reliability, and ease of use, it’s a system that helps reduce downtime, streamline operations, and support teams both on and off-site. For contractors, operators, and other firms, it’s a smart investment in better, more efficient site performance. Get in touch to find out more or to arrange a demonstration.